A fibre for all seasons

A NEW fibre developed by the British textile firm Courtaulds - Lyocell - is causing considerable interest in the markets in Europe, and now in India. Courtaulds claims that Lyocell blends the favourable qualities of cotton with those of synthetic fibre, and can be mass produced in an envirpnment friendly process.

A NEW fibre developed by the British textile firm Courtaulds - Lyocell - is causing considerable interest in the markets in Europe, and now in India. Courtaulds claims that Lyocell blends the favourable qualities of cotton with those of synthetic fibre, and can be mass produced in an envirpnment friendly process.

Fibres like cotton are obtained from plants and are by nature comfortable, ecologically sound and completely biodegradable. Moreover, fabrics made from plant-based fibres (cellulosic) breathe and absorb moisture, with outstanding colour yields for bright and natural colours. On the other hand, synthetic fibres like nylon offer superior strength, are more stable, and retain their colour better than cellulosic fibres.

Fibres made from petrochemicals, however, are not easily biodegradable. In addition, they do not breathe or are planted to compensate for the loss", says Anil Agarwal, director of the Centre for Science and Environment, New Delhi. But Tencel's unique manufacturing process and its biodegradability score in a big way over the sourcing of its raw material.

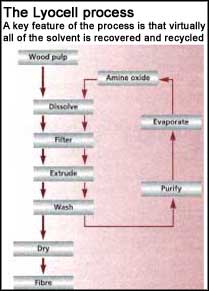

Unlike conventional viscose fibre, produced by chemically digesting the wood pulp leading to heavy gaseous emissions, the Lyocell process consists of pulpifying the raw material in amine oxide medium, which is fully recovered in the process and can be used continuously, to extract the fibre. The process lets out a negligible amount of emissions as a result.

Tencel has proven to be a strong fibre, whether wet or dry. Its tensile strength, claim Courtaulds, is much greater than that of cotton and even polyester, when dry. Being a 100 per cent cellulosic fibre, it absorbs moisture effectively, the reason why it gives comfort equal to that of cotton. "The fibre can be put to a variety of uses, both in the original form, as well as in blends with other synthetic and natural fibres," says M L Gulrajani, the head of the textile technology department at the Indian Institute of Technology, Delhi. He says the fabrics made by Tencel exhibit exceptional drape in luxurious handdyed and machine-dyed colours.

Lyocell also scores on fibrillation, or the coming out of the minute ends of the fibre when rubbed hard against a rough material, Courtaulds asserts. These minute micro-fibrils can be engineered to produce unique aesthetic effects. Tencel fabrics are gaining popularity with the top garment designers and labels in the fashion industry in the West.

Lyocell was introduced under the brand name Tencel in limited quantity in Britain in 1988. It was also marketed in Japan as a luxury fibre. Mass production began in 1992. At present, world- wide production of the fibre stands at 43,000 tonnes. "In the next five years it's going to explode, absolutely explode," says Michael Glasser, the Californian designer whose Democracy Jeans, made from Tencel, are already a hot favourite in the market. Italy's Georgio Armani says that Lyocell is a great fabric for sportswear. Many textile market experts predict that Lyocell will soon replace rayon and will also eat into the cotton and polyester markets.